Distress Reset

Rehabilitations

When a rehabilitation is applied, all distresses are assumed to reset to zero. The S-curve parameters are also reset using the updated values for Expected Surfacing Life and Distress Probability after rehab. The procedure for calculating the updated expected values for AADI, IV and T100 as discussed on this page.

In addition to re-evaluating the expected AADI and T100 values for each distress, an additional increase in the AADI value is provided through the use of an ‘AADI-boost factor’ to reflect the structural improvement provided through a rehabilitation. The ‘AADI-boost factor’ can be specified for each project/network through the use of a lookup table value held in lookup table ‘distress_reset’ against the key ‘rehab_aadi_boost’.

Re-Surfings (Preservation)

This section pertains to resetting distress when a re-surfacing is applied without extensive pre-seal repairs. See the section below on Holding Actions for adjustments made to these reset values when there is extensive structural repair associated with a re-surfacing

When distresses are reset, the values for AADI, IV and T100 needs to be re-estimated based on the newly updated expected surfacing life and the probability of distress.

The following distresses reset completely after a resurfacing as well as a rehabilitation type treatment. These are:

- Flushing

- Edge Breaks, and

- Scabbing.

Once the value for the distress is reset to zero, the probability is calculated and based on the new probability and expected surface life, the expected values for AADI, IV, and T100 are calculated as shown in Table 1 above.

However, for L&T Cracks, Mesh Cracks, Shoving and Potholes, the rate of deterioration after a resurfacing is a function of what the distress value was before the resurfacing. For these distresses, the values for the distress are also reset to zero. However, for these distresses the T100 and AADI values are adjusted to account for the magnitude of the distress before the reset.

The reasoning behind the reset model for L&T Cracks, Mesh Cracks, Shoving and Potholes is that the higher these distress percentages were before the resurfacing was placed, the quicker the distress will manifest again and the faster it will progress again. Thus, for these distresses, a resurfacing is assumed to have some marginal benefit (as explained below), but the distress is still latent in the pavement and will therefore manifest soon and then progress much faster than it would if a rehabilitation was performed.

Resurfacing - Reset for AADI

If the distress parameter value before the reset was below a certain limit (limit1), then AADI is not adjusted as it is believed that the distress were low enough to completely reset the distress parameter and associated AADI From limit1, the AADI will reduce linearly until it reaches a limit (limit2) beyond which no further reduction in AADI is expected. This also coincides with a AADI value of 1, which implies that the distress will start deteriorating in the next analysis year. All these limits are user defined in the lookup functions.

For the resetting of AADI, a piece-wise linear model is assumed between pre-set limits, as shown below:

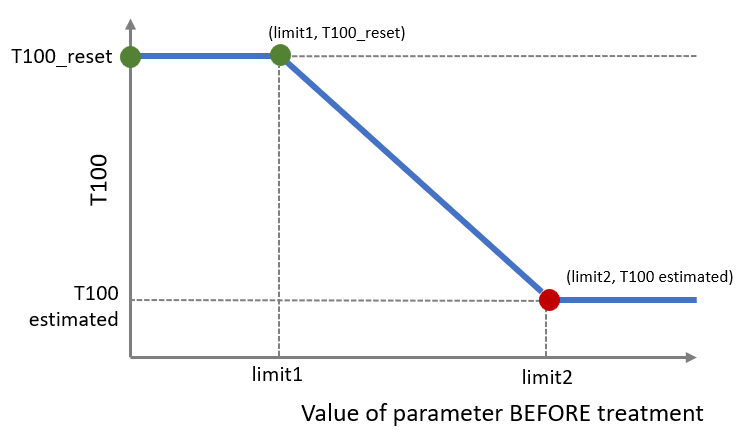

Resurfacing - Reset for T100

If the distress parameter value before the reset was below a certain limit (limit1), then the updated expected value for T100 is used as it is believed that the distress was low enough to completely reset the distress parameter and associated T100.

If, however, the distress was greater than limit1, the T100 will reduce linearly as the pre-reset value of the distress reduces to limit2. If the distress value before reset is greater than limit2, then an estimated T100 is calculated using the following steps:

- Estimate the annual distress percent progression by dividing the distress before treatment by the surface age before treatment.

- Calculate an estimated T100 based on the value calculated in step 1.

- Multiply the value calculated in step 2 with an adjustment factor (limit3 in lookup set) to take some improvement due to the resurfacing into account.

As an example for the resetting of T100 in the case of resurfacing, consider the following values defined in the model lookups for a particular distress:

- limit1 = 5 (if distress before reset is below this, then expected T100 value is applied)

- limit2 = 15 (if distress before reset is above this, then updated, adjusted T100 is applied).

- limit3 = 1.2 (previously estimated T100 is multiplied by 1.2 due to potential improvements by resurfacing)

For this example we assume the distress before reset is 20% and the surface age before reset is 10 years.

Since the distress is above limit1, we are not applying the expected T100 value, but we need to estimate it using the distress and age before treatment. We get the following values from the procedure explained above:

- Approximate rate of distress progression before treatment = 18% divided by 10 years = 1.8% per year.

- Thus estimated T100 before treatment is 55.56 years.

- We assume treatment will have some benefit in extending T100, thus adjusted T100 is 1.2 x 55.56 = 66.67 years.

A final check is done to ensure that the updated value of T100 is between the overall minimum and maximum T100 values allowed (typically 5 and 150 years, respectively).

If the distress before reset was somewhere between limit1 and limit2, then a linear interpolation is made that will estimate T100 to be somewhere between (a) the expected value of T100 after reset; and (b) the estimated, adjusted T100 value calculated using the procedure noted above. For more information about the calculation of expected values for AADI and T100, see this page.

In the Juno Cassandra NZLA model, values for limit1, limit3 and limit3 are held in the lookup table named ‘distress_reset’. Separate values should be provided for each distress type.

Holding Actions

In the Juno Cassandra NZLA model, a Holding Action is defined as a treatment that provides a degree of structural repairs before a re-surfacing is applied. This would the treatment traditionally referred to as ‘Pre-Seal Repairs’. Normally, in the case of a Chipseal surface, a second coat would be applied over the structural repairs in the following year. In the case of an Asphalt surface, the re-surfacing or overlay will normally be applied in the same year, although this will appear as two consecutive treatments in the Juno Cassandra output because Cassandra cannot apply more than one treatment in a year.

When a Holding Action is assigned, the resets applied to Visual Distresses are the same as for Re-Surfacing (explained above) except that the time to distress (re)initiation is extended somewhat to account for a degree of structural improvement. Thus, for Holding Actions, the AADI is determined as:

- (AADI as determined for Re-Surfacing) plus (AADI Boost Factor)

Where the AADI Boost Factor is specified in years (e.g. value of 3 to add 3 years to AADI) and is held in the ‘resets_general’ lookup table. A separate AADI boost factor should be supplied for each distress type.